Although the focus of this site is Biological Control in Greenhouses, it cannot be considered in isolation and without a broader understanding of Integrated Pest Management (IPM).

Definition of IPM

There are many definitions of IPM as a quick on-line search will demonstrate. However, there are several common threads which run through most of them.

- It is decision-based pest management (i.e. it uses monitoring information and biological understanding of the pest to assist in making decisions that keep pest populations below a level where they cause economic damage).

- It involves a diversity of control strategies (often for multiple pests). The “integrated” component of IPM reinforces the concept that control strategies need to complement, rather than conflict with each other.

- IPM does not necessarily exclude the use of pesticides. However, there is a strong ecological focus to IPM, that in most definitions emphasizes the use of alternatives to pesticides.

- It must provide economic benefits to the grower.

- The concept of IPM was originally developed in the late 1950s in response to concerns over environmental impacts of widespread use of synthetic pesticides, and the concepts have not changed appreciably since then 1. (See “The 50th Anniversary of a Great Idea”, Jeannette Warnert, California Agriculture“)

- For this web site, we do not propose a new definition of IPM, however, the points outlined above are central to our understanding of the concept. The focus of this site is Biological Control within the context of a broader IPM program.”

Monitoring

Monitoring provides reliable information to guide the decision-making process in an IPM program. It provides the means of detecting problems early, allowing for more effective and (often) localized action. Good record-keeping is a key part of a monitoring program.

One of the most widely used greenhouse-monitoring techniques is yellow sticky cards or tape (Figure 1, Figure 2) which are used to collect many species of flying insects. These are especially effective for whitefly, thrips, leafminer, fungus gnats, shoreflies and winged aphids. Note that blue sticky traps have been reported to be more attractive than yellow to western flower thrips 2, but there can be inconsistencies based on the UV reflectance, background and crop3. If a variety of pests is present, yellow traps are a better choice.

When using sticky cards, provide sufficient numbers to adequately monitor the entire greenhouse. There is no exact density of cards that is correct for monitoring purposes. The number needed may vary depending on the size and configuration of the greenhouse, and the crops being grown. For example, a small greenhouse with many different spring crops may require a greater density of sticky cards than a large greenhouse with only one crop.

- For most situations in ornamentals, use one card every 100–200 m2 (1,000-2,000 ft2) and change the traps regularly. In spring and summer, this usually means changing the cards every week when recording the pest numbers. In winter, when pest numbers are lower, it may be possible to change sticky cards less frequently, however pest numbers should still be recorded weekly.

- In vegetables, the number of cards used is on average 25 to 75 per ha. Cards are only changed when they lose their stickiness or become too crowded. As for ornamentals, pest numbers are recorded weekly.

- Sticky cards are available in different sizes from a number of different companies. There is no one size that is better than others. The key thing is to be consistent in your use of monitoring materials. Changing the source of cards may result in fewer or greater numbers of insects caught if the size of cards or the colour is different.

Another important monitoring technique is a routine and structured crop inspection program. It is essential for monitoring the presence of plant diseases, mites, wingless aphids or the immature stages of whitefly and leafminer. Adopt a regular sampling pattern that provides good coverage of the whole greenhouse, including entry points and areas of concern. Concentrate on known susceptible crops or areas within the greenhouse that are known hot spots. Again, keep weekly records.

To monitor for disease, inspect foliage weekly and roots (or, for vegetable crops, the bases of the plants) every two weeks. Check electrical conductivity (EC) and pH of the growing medium biweekly for each crop grown. To be successful, monitor on a regular basis.

Record information so it can be used in the future. Some growers record information on hard copy and keep each week’s records on file; others use spreadsheets that they have adapted to suit their own needs; and there are a number of software programs available specifically produced for crop monitoring. Important information may include:

- date

- pests identified

- location in the greenhouse

- number of insects trapped

- stage of development

- diseases present or suspected

- crop species and cultivar

- control action (pesticide used or BCA introduced, rate, area treated, time taken, etc) and results obtained

- environmental conditions

- Figure 1

- Figure 2

Cultural Controls

Cultural control options include a number of strategies that can be thought of as best management practices in the production of the crop.

Sanitation

Good hygiene is the first step in any pest control program. If a source of infection or infestation persists due to poor sanitation, pest control programs will be expensive and frustrating. Cleanliness on its own may not control pest problems, but it is a basic component of any control program and an essential adjunct to other pest management strategies. It is important to:

- Remove dead and dying leaves and flowers. For example in roses, removal of all flowers (including those that will not be sold) and disposal away from the greenhouse can play a significant role in control of thrips.

- Remove crop residues. Preferably burn them as permitted by the local municipality; alternatively, bury residues, or contain and dispose of them well away from the greenhouse.

- Hang hoses up so that the nozzles are clear of the ground

- Keep walks and the surfaces of beds clean. Clean benches between crops.

- For vegetable operations, wash and disinfect structure, irrigation lines, and all tools and equipment between crops.

- Maintaining warm temperatures in an empty greenhouse, completely devoid of vegetation and moisture for several days, can significantly reduce pest survival and carryover to the next crop4.

- Check carefully for pest infestations when bringing new plant material into the greenhouse.

- Avoid overwintering garden or house plants in the greenhouse, otherwise pests will be maintained for an early invasion of the next crop.

Weed control

Remove all weeds from inside (Figure 3) and immediately outside the greenhouse (Figure 4). They can provide a refuge for pests and act as a reservoir for diseases.

Environment

Factors such as light, temperature, humidity, water and nutrients affect not only the plant, but also the pests and diseases that afflict them. The use of environmental controls to manage pests is complex because of the simultaneous effects on crop production. Look at each case carefully; every one is different.

Humidity can play an important role in pest and disease development. Humidity (greenhouse vegetable growers often work with a related but slightly different concept known as Vapour Pressure Deficit – VPD) can be affected by temperature, airflow, plant spacing, irrigation (timing and technique) and greenhouse structure. Management of humidity is important in the management of foliar diseases such as powdery mildew and Botrytis. Pests such as spider mites prefer hot, dry conditions and increasing humidity with overhead misting can help to retard the development of this pest.

During the winter months, insects are not particularly mobile. This may be due to low light levels (rather than to low temperatures) and it can have implications for monitoring programs. For example, if thrips are not flying because of environmental conditions, they will not be caught by yellow sticky cards, even if they are present and actively feeding in the crop.

Maintain good drainage to eliminate puddles and wet surfaces, as these provide ideal breeding sites for fungus gnats and shoreflies, and are a possible source of infection for waterborne diseases.

If the greenhouse is empty between crops, heat treatment can be an effective way to remove pest infestations. If temperatures are maintained at >40°C and humidity at <50% for 3–4 days, insect and mite pests will be effectively controlled4. This is particularly suitable during the warmer months of the year when these temperatures can be achieved by simply closing the vents. Note: At higher temperatures, plastic fittings may warp.

Cultivar Resistance

Many plant species display varietal differences in their susceptibility to insect and disease attack. Breeding of crops can provide growers with cultivars resistant to one or more insects or diseases. For example, greenhouse tomato growers seldom experience problems with Fusarium crown and root rot because resistant varieties have been developed. Greenhouse growers are increasingly using powdery mildew–tolerant cucumber varieties. Although ornamental plant breeders have not taken great advantage of host plant resistance, it offers potential for future advancements in pest management.

In the meantime, growers with pest problems can improve their pest management program by examining the varieties grown and how pests affect these varieties. Use susceptible varieties as indicators for pests and diseases (e.g. the colour of the flower might attract more thrips) or as a means of making monitoring programs more efficient. Use susceptible varieties as an intensive focus of biological control programs. Although market demands ultimately determine the varieties grown, consider whether it is possible to eliminate or reduce the amount of a susceptible variety and replace it with a more resistant one.

- Figure 3

- Figure 4

Physical Controls

Screening

In warmer climates where pests occur outside all year, screening has become an established part of IPM programs. While not as common in temperate areas, screening is becoming more accepted and its value more apparent.

Screening can greatly reduce the entrance of common greenhouse pests such as thrips, aphids and whiteflies, as well as some less common pests such as plant bugs and various moth pests, which can become major pest problems when pesticide use is reduced (e.g. in biological control programs). Benefits of using insect screening have been demonstrated in Israel and California. In Ontario, Canada, growers who have installed screens have reported that pest levels and pesticide use are reduced and effectiveness of pest control measures (especially biological control) improved.

The most important consideration for a grower wishing to screen a greenhouse is to determine which pests need to be excluded. The size of the pest determines the mesh size of the screen that is needed. Large mesh sizes of the style normally found in household screens are inadequate for excluding most major greenhouse pests; however, they can be useful in keeping out occasional larger pests such as tarnished plant bugs and lepidopteran (moth) pests. For smaller insects such as thrips, screens must be made of a very fine mesh for total exclusion. In cases with multiple pests of concern, mesh size should exclude the smallest of these pests.

A major concern for many growers is that screening will reduce airflow, making it difficult to maintain the correct environment. If this happens, it can lead to the greenhouse overheating and stress on the fans (in the case of fan-ventilated greenhouses), which must work harder to pull the same amount of air through the vents that are, in effect, partially blocked. Reduced ventilation is a valid concern, but it can be addressed by increasing the surface area of the vent. In many situations this has been completed successfully by building a screened framework around the vent opening (Figure 5A, Figure 5B, Figure 5C). The goal is to ensure that the final surface area of the vents provides sufficient air exchange to allow adequate cooling of the greenhouse. There are several methods available to determine the required increase in surface area of the vents for any given greenhouse, but factors such as screen mesh size, fan capacity and static pressure drop (the difference in air pressure between inside and outside the greenhouse when the fans are running) are important. Although there are software programs available to assist with these calculations, they can be complicated and are generally best left to screening manufacturers.

The small mesh size means that the screens are very prone to blockage with dust and other deposits, especially in the summer. Such blockage will reduce airflow through the screens and may contribute to excessively high temperatures in the greenhouse. Therefore, clean the screens regularly. It is also important to incorporate easy access in the design of the screens to facilitate their cleaning. Wash screens from the inside with a high-pressure hose. Do not do this when the fans are operating, because the water will block the pore openings and completely stop airflow, leading to overheating of the greenhouse.

The effectiveness of the screen depends on its ability to exclude flying insects. Repair tears or holes as soon as possible to avoid pest entry. Small tears can be simply repaired by gluing a piece of screening over the hole.

The cost of screening will depend on several factors: the final screening design, the increase in surface area needed to maintain adequate ventilation, the cost of the screening material, whether roof vents or side vents are to be screened, frequency of replacement, frequency of cleaning, etc. The biggest variable is the difference in cost between installing screens in a fan-ventilated, side-vented greenhouse or a passively vented greenhouse with roof vents. Nevertheless, reports from growers who have installed screens over side vents in fan-ventilated greenhouses suggest a rapid payback from reduced pesticide costs and improved pest management.

For more information, see references 5,6,7.

Other Physical Controls

Yellow sticky tape can provide additional control of flying insect pests8,9. It works on the same principle as the sticky cards used for monitoring. String tape along plant rows, beds or benches or hang it vertically within the crop to provide useful supplementary control in conjunction with other control methods.

Sticky tape can come in a variety of widths (5 cm – 30 cm) (Figure 6) and in rolls up to 500 m long. It can be messy to apply, but it can remain in place for as long as it is continuing to catch insects – at least several months.

There are a number of ways in which it can be applied and used and growers can be very creative in its application: finding ways to raise and lower it out of the way so that it doesn’t interfere with crop production practices; attaching it to movable booms so that it actively disturbs and catches insects as it is moved across the crop; or leaving it stationary and allowing passive insect trapping by relying on the attractiveness of the yellow colour.

Be aware that using large quantities of yellow sticky tape may be detrimental to a biocontrol program which uses flying insects (e.g. parasitic wasps), since they will also be attracted to the tape. For biocontrol programs based on predatory mites however, the sticky tape can give useful additional control.

- Figure 5A

- Figure 5B

- Figure 5C

- Figure 6

Biological Controls

Biological control (biocontrol) is the use of living organisms such as insects, mites, nematodes, fungi and bacteria to control pests such as insects, mites and diseases. Biocontrol requires very different approaches for vegetables and ornamentals. While it is has been widely used in greenhouse vegetable crops for many years, it is only since the late 1990’s that it has become more widely used in ornamentals. The development of resistance to pesticides is a primary reason for increasing use of biocontrol in ornamental crops10

Biocontrol is only one component of an IPM program and cannot stand alone. It requires the support of other strategies described above; e.g. a proper monitoring program, cultural controls (e.g. good sanitation, weed control, environmental management), physical controls if appropriate and use of compatible pesticides.

Biocontrol is the primary focus of this site however its place in a broader IPM program must be kept in mind.

Definitions/Terms

Biocontrol comes with its own glossary and use of specific terms. Below is a list of commonly used terms that you may find on this site or in other information on biocontrol. It is useful to have an understanding of these terms and what they mean:

- BCA is an acronym for biocontrol agent of which there are a number of different types. Many are produced commercially, while others may be naturally occurring in certain areas.

- Predators feed on their prey by catching it but otherwise live independently of it. They must consume more than one individual to reach maturity. The most commonly used predators are the predatory mites, but others include true bugs, midges (a type of fly) and beetles.

- Parasitoids usually require only one host for completion of development, often killing it by living on or in its body. The most commonly used parasitoids are parasitic wasps (Figure 7).

- Arthropods are (usually) small animals with jointed exterior skeletons. The primary arthropods of interest from a greenhouse biocontrol perspective are insects, mites and spiders.

- Insects are six-legged arthropods. There are hundreds of thousands of known species of insects and many more still to be discovered, but the most important in terms of biocontrol are those in the groups known as wasps, flies, beetles and true bugs.

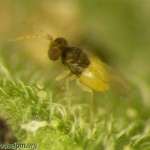

- Wasps belong to a group of insects that includes ants and bees. In greenhouse biocontrol, the wasps used are generally quite small (<2-3mm) (Figure 8).

- Flies are different from many other insects in possessing only one pair of wings (most other flying insects have 2 pairs). Flies important in biocontrol include the predatory midges (e.g. Aphidoletes and Feltiella). Others such as hunter flies (Coenosia) and hover flies (also known as syrphids or flower flies) are not produced commercially for use in the greenhouse but often enter naturally from outside when pesticide use is reduced (Figure 9).

- Beetles include insects such as lady beetles (also known as coccinellids – lady beetles in French is “coccinelles”) and rove beetles. Lady beetles include the well known spotted insects we see in the garden, but also predators such as Delphastus, Stethorus and Cryptolaemus are part of this group (Figure 10).

- Bugs are a type of insect but the word is often used as a general term (and incorrectly) for any insect. For this reason, the term true bug is often used so that there is no misunderstanding. True bugs have sucking mouthparts and include insects such as Orius, Dicyphus and (in Europe) Macrolophus (Figure 11).

- Life stages of insects and mites have their own terminology. The immature stages of insects (there may be several before they become adults) may be referred to as larvae or nymphs, and each individual stage can sometimes be referred to as an instar. Following the younger immature stages, there is often a pupal stage which is a non-feeding dormant stage in which the adult develops. The above is a very simplistic description; it is just important to note that these terms refer to immature insects and mites.

- Insects may be referred to as disease vectors. This means that they can transmit diseases between plants either actively (e.g. by feeding on a plant, acquiring the pathogen and then transferring it while feeding on another plant), or passively by picking up pathogens (e.g. externally on their body) and transferring them to other plants as they move around. It should be noted that humans can also act as vectors when they perform crop maintenance procedures such as harvesting, pinching or disbudding.

- Diapause is the insect equivalent of hibernation. During winter, some insects become inactive and stay that way until conditions improve in the spring. The trigger for diapause is often decreasing day length and/or temperature. Diapause affects some pests, but it can also affect some BCA’s, e.g. Orius, Aphidoletes, which cannot be used during winter months.

- Mites and spiders are 8-legged arthropods. Spiders can be important in biocontrol programs, but are not produced commercially. However in greenhouses where biocontrol is used and pesticide pressure is reduced, they will often develop large populations naturally. Mites are commercially very important predators (Figure 12). They are used for control of a number of pests including thrips, whiteflies, spider mites and fungus gnats.

- Microbial BCAs are those that are generally too small to be seen with the naked eye. The most commonly used microbials are nematodes, fungi, bacteria (or bacterial toxins) and viruses. Nematodes are microscopic roundworms (Figure 13). Some species control various insect pests by entering through body openings and releasing a bacterium that produces toxins which kill the insect. The nematode then feeds on the decomposing tissue and reproduces.

- Some species of insect pathogenic fungi can infect various insects, killing them in the process. A number have been formulated into pest control products. In many countries these products need to be registered in the same manner (or similar to) that of pesticides. Insect pathogenic fungi include Beauveria bassiana, Metarhizium anisopliae, Paecilomyces fumosoroseus and Verticillium lecanii.

- Bacteria as biocontrol agents are most commonly represented by the bacterial toxin produced by Bacillus thuringiensis also known as Bt. This toxin is formulated as a pesticide and has to be registered as such, however, they are very compatible with other BCA’s. There are a number of different strains of Bt, which are effective against different types of insects. For example, Bt israelensis (Bti) is active against the immature stages of flies such as fungus gnats and mosquitoes; Bt kurstaki (Btk) against caterpillars of moths and butterflies (Figure 14); Bt tenebrionis (Btt) against the larvae of beetles.

Scientific Names of Organisms

For growers new to biocontrol, one of the most difficult things to come to terms with is the widespread use of scientific names to describe the various BCA’s. This is because so few of them are familiar enough to have attracted the use of a common name. While that may seem to be unfortunate, it actually allows us to be much more precise. With the use of scientific names, there can be no misunderstanding as to which organism is being discussed. With common names, the same insect may have different names in different countries or regions, leading to confusion when discussing it.

Scientific names consist of two words, the first being the genus which consists of a group of fairly closely related organisms. The second word is the species name. The two words together describe one species of organism. It is usual to write them in italics with the genus capitalized. For example, the parasitic wasps Aphidius colemani and Aphidius ervi are two closely related, but different species which attack different species of aphids. When a scientific name is being used several times in the same document it is often shortened for convenience, with the genus being abbreviated to the first letter. Thus we use A. ervi with the understanding that we are talking about an Aphidius species because we have already been discussing it. The first time it is mentioned it is given its full name and thereafter it can be abbreviated. In conversation, many of the names of these BCAs are shortened even further for convenience and simplicity; so we hear talk of “persimilis”, “cucumeris” or “Orius”.

It should also be noted that even though the use of scientific names is supposed to make it perfectly clear exactly which organism we are talking about, it does not always work quite as it is supposed to. You will find as you read various articles, books and company catalogues, that different names are sometimes used for the same BCA. For example, Neoseiulus cucumeris is also called Amblyseius cucumeris. Amblyseius degenerans can be called Iphesius degenerans. These discrepancies are the result of ongoing discussion among taxonomists as to exactly how these different predatory mites should be classified. Where multiple names are used for the same BCA, this has been noted in the detailed information for each individual BCA’s.

Although the names of many of the BCA’s can appear complicated when they are first encountered, with practice they become familiar.

How to set up a biocontrol program?

Biological control involves more than just the release of parasites or predators. To be successful, plan at least several months in advance.

Follow these steps when considering the use of biological control:

- Develop a list of resources to help with the program (this may include producers and/or suppliers of biocontrol agents, other growers, extension specialists, researchers or consultants).

- Attend courses, seminars and workshops; read magazines and newsletters; use the Internet to find out as much as possible about biocontrol.

- Determine which pests to control and the most appropriate natural enemies to use.

- If possible, start in a small and isolated part of the greenhouse to focus more closely on the area being used, and to gain some experience with biological control before applying the concepts on a larger area.

- After reaching a level of comfort with biological control, expand the use of natural enemies to include other areas of the operation.

- If possible, screen the area to be used. Movement into the greenhouse of pests from outside is unpredictable from year to year. Large numbers can swamp a biocontrol program and make it difficult for the natural enemies to maintain control. With screening, growers need only be concerned about the pests inside the greenhouse. Note, however, that screening will also exclude naturally occurring BCA’s that could contribute to the success of biocontrol program. The advantages and disadvantages of screening need to be weighed based on whether there is more to be gained from excluding potential pests or beneficials.

- Ensure that all staff is aware of the biological control program and why it is being used. They are in the greenhouse every day performing routine crop management tasks and with proper training can recognize problems at a very early stage.

- Many registered pesticides can have long-term (2–3 months) residual impact and can prevent the establishment of natural enemies. Check pesticide spray records for the previous several months. If such pesticides have been used, wait the appropriate length of time before starting. Use products with less residual impact to control pests and diseases during this period. Side effects of many pesticides on different biocontrol agents are available in hard copy from the biocontrol suppliers or on the internet from Biobest (www.biobest.be), Koppert (www.koppert.com) or Natural Insect Control (www.naturalinsectcontrol.com).

- Work with the supplier to learn how to check incoming biocontrol agents and determine if they are alive and well. The quality of natural enemies produced by the commercial insectaries is generally excellent, but problems can occasionally arise in shipping. Suppliers need to know about any problems in quality so the causes can be identified and corrected.

- Follow instructions in storing and releasing the natural enemies. Many can be stored for only a short period of time under fairly specific conditions.

- Monitor the populations of natural enemies and the progress of the biocontrol program. This is as important as monitoring the pest populations.

- Use sticky cards to monitor flying insects, especially the parasitic wasps. Be aware however, that some natural enemies (e.g. Eretmocerus for whitefly control) are highly attracted to yellow, and too many sticky cards may be detrimental to the program.

- Check the impact of the natural enemy on the pest. For example, parasitism of whitefly by Encarsia and aphids by Aphidius parasitic wasps is easily checked.

- Visually inspect the crop for natural enemies such as predatory mites, which do not fly. Inspect the crop especially in areas of highest pest numbers.

- Regularly monitor pests to determine if populations are decreasing.

- Use compatible pesticides if necessary. Such pesticides should be identified prior to starting a program so they are available and can be used if necessary.

- Contact your biocontrol suppliers for more information on pesticide compatibility. (Biobest www.biobest.be, Koppert www.koppert.com, Natural Insect Control www.naturalinsectcontrol.com)

- Be patient. It takes time and experience to understand and implement an effective system of biocontrol. Ask others with experience if the program is not progressing as expected.

Vegetables vs Ornamentals

There are differences between using biocontrol in vegetable crops as opposed to ornamentals. Biocontrol has been used in greenhouse vegetable crops since the 1970’s. Biocontrol in ornamentals is a much more recent development and while many of the strategies and biocontrol agents that were developed in vegetables have been successfully transferred to ornamentals, there are also instances where strategies that work in vegetables do not work in ornamentals.

In vegetables, there are only 3-4 major crops and individual growers are usually working with a single crop in each production area. This makes it easier to develop programs that have broad application. In ornamentals, although there are greenhouses where large areas are planted to single crops, more often there are multiple crops in the greenhouse at one time and different crops seasonally. For example, growers of spring crops may have >100 plant species in the greenhouse with multiple varieties of each. They may be grown as hanging baskets with a 3 month growing period, as potted crops for planting out, or as small cell packs. They may be hung from the superstructure of the greenhouse, grown on benches or on the floor.

The greater number of plant species present in many ornamental greenhouses results in a potentially larger pest complex.

Ornamental crops are grown strictly for their appearance and therefore have a lower threshold for pests and pest damage than vegetables. Vegetable crops can sustain some damage to the foliage as long as the fruit quality is maintained.

The uptake and potential for success of biocontrol in a crop is often associated with factors other than the inherent effectiveness of a particular BCA. For example, in vegetables, the development of insect pollination in the early 1990s provided great incentive for growers to reduce pesticide use in crops such as tomatoes and peppers. The issues around pesticide residues on food, and potential marketing advantages of reduced pesticide use, provided similar incentives to make biocontrol work. In ornamentals such inducements to use of biocontrol do not exist or are not as relevant, but development of pesticide resistance and lack of new pesticides have meant that growers in some regions have had no choice but to make biocontrol successful10.

- Figure 7

- Figure 8

- Figure 9

- Figure 10

- Figure 11

- Figure 12

- Figure 13

- Figure 14

Chemical Controls

Pesticides will continue to be important in greenhouse IPM programs, however their role changes from that of the primary control strategy to a more supportive role. Many of the older broad spectrum pesticides (e.g. organophosphates, carbamates and synthetic pyrethroids) have a greatly reduced role to play within the context of IPM, since they often have long-term (up to 2-3 months) persistence and activity against biocontrol agents. It is important to note that the persistence of many pesticides can carry over on vegetative cuttings. New crops grown from cuttings produced in another location, may carry pesticide residues that could impact the establishment and success of biocontrol agents. Contact the propagator for information on pesticides that have been used on the mother stock plants.

Many newer pesticides are much more specific in their spectrum of activity which offers the potential for integration with biocontrol. Information on the side-effects of many pesticides against various biocontrol agents is available on-line (Biobest www.biobest.be or Koppert www.koppert.com).

However, it should be noted that the information on pesticide compatibility in these side effects lists should be treated as guidelines only. The values are based on acute toxicities of the various pesticides; (i.e. how many are killed and for what period of time the pesticide residues will continue to affect the various BCA’s). It does not take into account other effects on the BCA’s such as the number of offspring produced, searching behaviour, life span etc. Additionally, there may be differences in the values given on different lists. If there are differences, use the more conservative value. It should also be noted that some pesticide active ingredients may have information available on one site but not on others and the same applies to BCA’s.

It is important to note that the objective of this web site is not to offer pesticide recommendations. Pesticide registrations are a national responsibility and as such vary among countries. Contact the appropriate government agency in your country to determine the registration status of individual products or active ingredients.

References

1Stern, V. M., R. F. Smith, R. van den Bosch, and K. S. Hagan. 1959. The integrated control concept. Hilgardia 29: 81–101.

2Brødsgaard, H.F. 1989. Coloured sticky traps for Frankliniella occidentalis (Pergande) (Thysanoptera: Thripidae) in glasshouses. Journal of Applied Entomology, 107: 136-140.

3Lewis, T. 1997. Field and laboratory techniques. In: Thrips as Crop Pests. (ed: T. Lewis), CAB International, Oxon, UK.

4Shipp JL, Gillespie TJ, 1993. Influence of temperature and water vapor pressure deficit on survival of Frankliniella occidentalis(Thysanoptera: Thripidae). Environmental Entomology 22, 726-732.

5Murphy, G and Ferguson, G. 2000. Screening of greenhouses for insect exclusion. Ontario Ministry of Agriculture, Food and Rural Affairs FactSheet, Agdex 290/626, Order No. 00-021. http://www.omafra.gov.on.ca/english/crops/facts/00-021.htm

6Bell, M.L. and Baker, J.R. 1997. Choose a greenhouse screen based on its pest exclusion efficiency. North Carolina Flower Growers Bulletin, 42(2): 7-13.

7Bethke, J. 1994. Considering installing screening? This is what you need to know. Greenhouse Manager, April, 1994, pp34, 36, 37.

8Gillespie, D.R. and Quiring D. 1987. Yellow sticky traps for detecting and monitoring greenhouse whitefly (Homoptera: Aleyrodidae) adults on greenhouse tomato crops. Journal of Economic Entomology, 80: 675-679.

9Moreau, T.L. and Isman, M.B. 2010. Trapping whiteflies? A comparison of greenhouse whitefly (Trialeurodes vaporariorum) responses to trap crops and yellow sticky traps. Pest Management Science, 67: 408-413.

10Gates C. and Watson, G.R. 2010: Development of risk reduction strategies in ornamental horticulture. Final report of Project PRR09-060

External Links

Further Reading

Heinz, K.M., Van Driesche, R.G. and Parrella, M.P. 2004. Biocontrol in Protected Culture (eds: K. M. Heinz, R.G. Van Driesche and M.P. Parrella), Ball Publishing, Batavia, Illinois, 552 pp.

Malais M.H and Ravensberg W.J. 2003. In Knowing and Recognizing: The biology of glasshouse pests and their natural enemies. Koppert BV, Berkel en Rodenrijs, The Netherlands and Reed Business Information, Doetinchem, The Netherlands.